Drax power plant operation 8: carbon emissions from biomass fuel

date:2020-07-29 16:40:45

British Drax 6*660MW power plant biomass fuel power generation operation, introduces the operation of Drax power plant from multiple angles and links. Section 7 introduces the power plant biomass development decision-making, this section introduces the carbon emissions of the Drax power plant biomass fuel power generation.

Biomass energy is considered a renewable energy because its energy comes from the sun and can be regenerated in a relatively short period of time; Biomass energy is considered a green energy because plants absorb it from the atmosphere through photosynthesis Carbon dioxide is fixed and converted into biomass itself; biomass is considered a clean and environmentally friendly energy source, because the concentrated collection and utilization of these discarded biomass raw materials for power generation can avoid fermentation and decomposition of greenhouse gases in nature Fires caused by methane, CH4, etc., and dust pollution from open burning.

Nevertheless, in addition to the transmission of raw materials in the power plant, crushing and milling, flue gas treatment and other links that consume plant electricity, biomass power generation will still generate carbon during the planting, harvesting, pretreatment, and transportation of the fuel before the fuel enters the plant. emission. So, how high is the carbon emissions of Drax's biomass power generation? What work has Drax done to reduce the carbon emissions of biomass energy utilization as much as possible?

To this end, Drax has carried out a high degree of monitoring and attention to each step of the biomass raw material supply chain, calculating and reporting the emissions at each stage and link to ensure that its clean and low-carbon requirements are met, and calculated according to regulatory requirements Greenhouse gas (GHG) emissions associated with controlled biomass fuels. Drax requires each supplier to provide detailed information on what kind of basic biomass raw materials are used to make biomass pellet fuel, as well as its source, the distance to the processing plant, the type of transportation vehicle, the detailed production process of biomass pellet fuel, and the production process. The energy and energy data used in the processing of material particles, any shipping data (including the type of ship used, which shipping route, detailed distance, etc.). Drax also uses the British Solid and Gas Biomass Carbon Calculator to calculate greenhouse gases for all materials consumed. The calculator uses the method specified in the EU Renewable Energy Directive, which is reported to the Gas and Electricity Market Office (Ofgem) monthly .

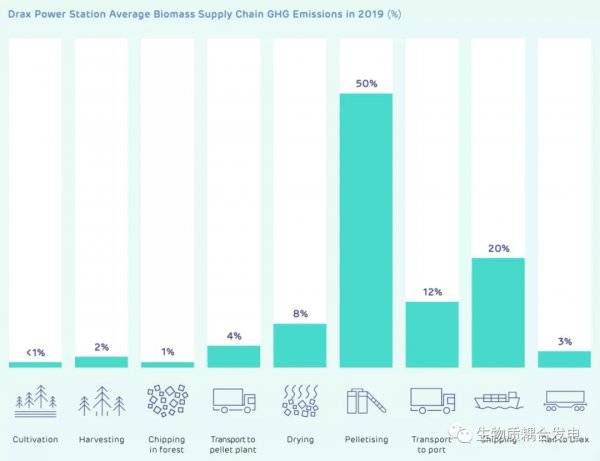

Because greenhouse gas emissions are affected by many factors, including planting, harvesting, fuel pre-processing and transportation, etc. The reality is that most of Drax's biomass pellets are shipped from North America to the United Kingdom, and the highest proportion of its greenhouse gas emissions are energy consumption during the production of biomass pellets and marine emissions during transportation.

The impact of ship emissions depends on the distance and the size of the ship. For this reason, Drax requires that for long-distance (for example from North America) routes, large ships capable of transporting more than 40,000 tons of biomass fuel (sometimes up to 60,000 tons) must be used. This greatly reduces the emissions per ton of biomass fuel. In mainland Europe, the transportation distance is much shorter, so smaller ships can be used, which allows ships to directly enter small ports that can shorten transportation within the UK.

After the biomass fuel entered the British port, Drax used a railway train specially designed for biomass fuel transportation to transport the fuel directly from the port to the feed inlet of the four biomass fuel storage bins of the power plant. This is significantly lower than the carbon emissions of road transportation, and while the transportation capacity is greatly improved, the cost is also greatly reduced. Considering that biomass fuels outside the UK are often transported to export ports by road trucks, the ideal location for overseas biomass fuels is close to biomass raw materials and ports to minimize carbon emissions from inland transportation.

The British government has set a limit on the greenhouse gas emissions of the biomass energy supply chain. Biomass power plants must meet this limit before they are eligible to receive support from renewable energy obligations and contract for difference programs or government subsidies. The current limit is 285g CO2/kwh, which will be reduced to 200g CO2/kwh by 2020.

British Bureau Veritas (an independent service company with a history of more than 190 years) has conducted an independent third-party review of the carbon emissions of Drax biomass power generation. The purpose is to inform stakeholders (including the government, the public, shareholders, management , Employees, suppliers, competitors, power users, etc.) to ensure the accuracy, reliability and objectivity of the reported information, and to ensure that it covers issues that are vital to the company and its stakeholders. The review period is from January 1, 2019 to December 31, 2019. The scope of work reviewed includes: carbon emissions; total recordable injury rate under health and safety performance; data on the number of employees listed by contract, country, business unit, and gender; water use data; biomass supply chain average greenhouse gas emissions, etc. Finally, the biomass fuel carbon emission data of the Drax Power Plant in 2019 is 124g CO2/kwh, which is slightly lower than 131 in 2018 and less than half of the UK government's limit value of 285.

As can be seen from the above figure, among the 124g carbon emissions, the carbon emissions during the planting process of biomass raw materials are 1%, 2% are collected or harvested, 1% is crushed before loading, and the road transportation from the raw material source to the biomass pellet processing plant 4%, 8% of raw materials drying in biomass pellet processing plants, 50% of biomass pellets processing plants crushing and granulation, etc., biomass pellets from processing plants to overseas export ports accounted for 12%, ocean transportation 20%, in the UK Railway train transportation 3%.

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.