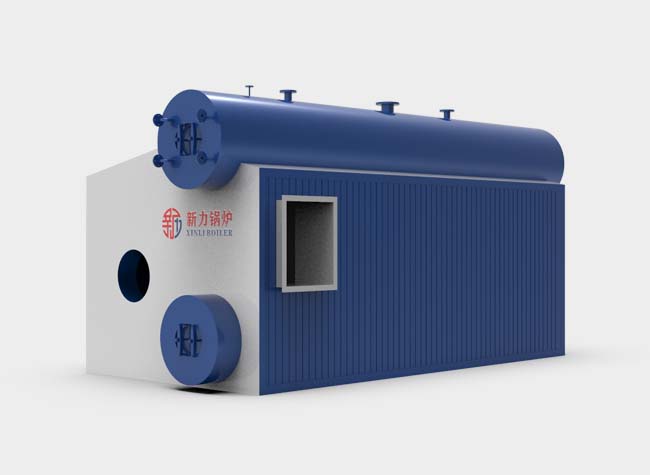

Sugar Industry Boiler

Sugar mills are enterprises that use large amount of heat and burn a lot of fuel. Generally, small and medium-sized sugar mills use bagasse as fuel. If the thermal energy utilization of the whole plant is properly arranged, bagasse can meet the production requirements without the additional burning coal or firewood. However, most medium-sized sugar mills and even some large sugar mills have higher coal burning due to problems of thermal energy arrangement. According to statistics, China's sugar industry USES about 1.5 million tons of coal every year. At present, the international energy crisis, countries need to find ways to save energy and find new energy.

In the sugar factory, steam is mainly used to generate electricity, concentrate sugar juice and dry sugar. Most sugar mills use bagasse and coal as fuel. The economic viability of sugar cane mills depends largely on the use of bagasse as fuel to generate power and steam for processing. In addition, other biomass fuels (wood, straw, etc.) can also be used to reduce the cost of boiler fuel. Petroleum and natural gas fuels can also be used in sugar refineries, which have the advantages of no pretreatment, continuous combustion and high combustion efficiency.

Boiler Model Selection used for Sugar Industry Boiler

In addition to providing steam used for sugar production process, the boiler of the sugar factory is generally equipped with a turbo-generator, namely combined heat and power generation. The electricity generated is also for the sugar factory itself, and the electricity can be basically self-sufficient. According to the actual needs of customers and the requirements of sugarcane and sugar plant construction, Xinli boiler makes the most suitable heating schemes for textile plants at home and abroad.

Boiler Model Recommendation

How to Choose the

Suitable Boiler for

Sugar Industry Boiler

Determine boiler capacity

Sugar production is characterized by high consumption of steam and low electricity consumption. The boiler is equipped with steam supply and turbo-generator to produce vapors for sugar-making process. In order to make rational use of heat energy and save energy, the method of co-generation of heat and power is generally adopted in the sugar refinery at present. The principle of determining electricity by steam is that the boiler steam output is subject to the process steam consumption while the power generation is determined by steam output.

Determine Boiler Pressure

In the past few years, the low-pressure boiler of 1.3mpa set up in Chinese sugar mills is unreasonable for the economic efficiency of steam and the utilization of heat energy in sugar mills. In recent years, the boilers of sub-medium pressure (2.5mpa) and Central Asia (4Mpa) are generally adopted in sugar mills, and remarkable energy-saving results have been achieved.

Steam Turbine Selection

The sugar factory is a seasonal production factory, which USES electricity and steam more smoothly during production, and the boiler also stops running during decompressing. The back-pressure steam turbine can meet the actual requirements of the sugar plant: high efficiency, combined heat and power generation, steam power. The inlet pressure of back-pressure turbine is usually 2.45mpa or 3.43mpa. High efficiency of heat energy, no need of condenser, simple equipment, relatively little investment, easy installation and maintenance.

Determine Boiler Efficiency

Boiler for sugar factory should be more efficient. The boiler output, the number of sets and other performance can adapt to the demand of heat load change, in order to facilitate economic management. If the use of one boiler operating at full load can meet the demand for steam, it is not appropriate to use two boilers operating under lower load. However, from the perspective of safety production, it is necessary to consider whether a single boiler in operation can be started quickly in a short time due to failure, so as to meet heating requirements without affecting production.

Capacity and Model

When boiler with different capacity and different types is selected, the boiler with the same capacity and combustion equipment should be selected. If not, try to construct the responsible line of equipment layout and maintenance management. The same model with different capacities or different models with same capacity could be choosed.

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.