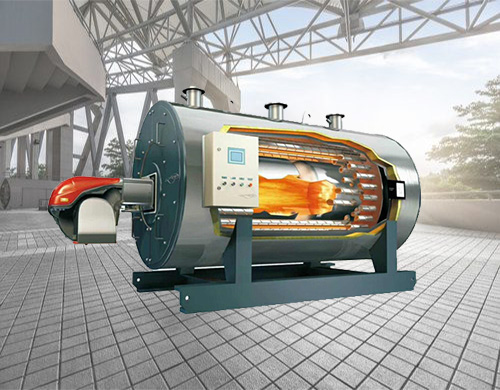

Gas boiler inspection specifications that operators must be familiar with

date:2021-11-01 09:19:45

A gas boiler is a complex and sophisticated stove. Its maintenance operations require professionals to deal with it. Ordinary individuals do not have the ability to deal with problems, so it is not recommended to deal with them privately. At the beginning of the operation, pre-start inspection, appearance observation, furnace internal inspection, etc. should be carried out.

1. Inspection before starting up

The inspection content includes whether the burner and related accessories and pipes are in good condition and whether the operation is flexible. After all inspections are normal, the boiler can be filled with water to start the fire. The boiler should be filled with water to the normal water level, and all air and flue baffles should be opened first. Turn on the blower to ventilate and purge the furnace sill and flue. The purge time shall not be less than 0.5 minutes, and then start the ignition device of the burner. The ignition and debugging of the burner should be handled by the burner manufacturer or the agent appointed by a special person. After the platform is adjusted, it can be put into normal operation with the boiler.

2, valve inspection

The boiler and safety accessories should be qualified and within the validity period. Conditions and inspection items that should be met before boiler operation: Open the natural gas supply valve. Check whether the natural gas pressure is normal and whether the natural gas filter is ventilating normally. Check whether the water pump is normal, and open the valves and dampers of various parts of the water supply system. The flue should be in the open position in the manual position, and the pump selection switch on the electric control cabinet should be selected in the appropriate position;

3, ignition and boost

After the boiler is ignited normally, the temperature should be raised slowly to make the expansion of the furnace wall and the furnace body uniform, and the pressure from the cold furnace ignition to the working pressure is generally controlled within 3 to 4 hours. When the steam pressure rises to 0.06 ~ 0.1MPa, the boiler pressure gauge and water level gauge should be flushed to keep it working; when the boiler steam pressure rises to 0.15~0.2MPa, close the air valve and check whether the safety valve leaks, if any Leaks should be immediately taken to remove; when the boiler pressure is increased to 0.2 ~ 0.25MPa, the boiler drum should be polluted once. The boiler water level should be at the highest water level during the blowdown. After the blowdown, check whether the blowdown valve is tightly closed and whether there is any leakage. Phenomenon: When the steam pressure rises to 0.3MPa, it is necessary to comprehensively check the fasteners of the pressure components of the boiler, such as manholes, hand holes, inspection holes and the bolts of each flange for looseness, and perform one-time hot tightening; when When the boiler steam pressure rises to the working pressure, adjust the safety valve.

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.