Boiler Used for Hotel

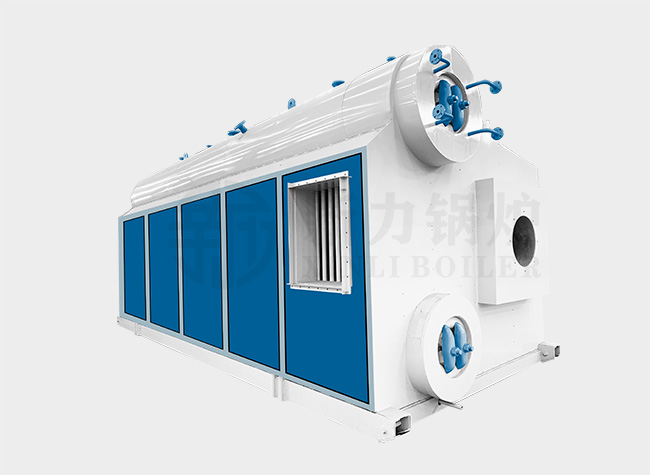

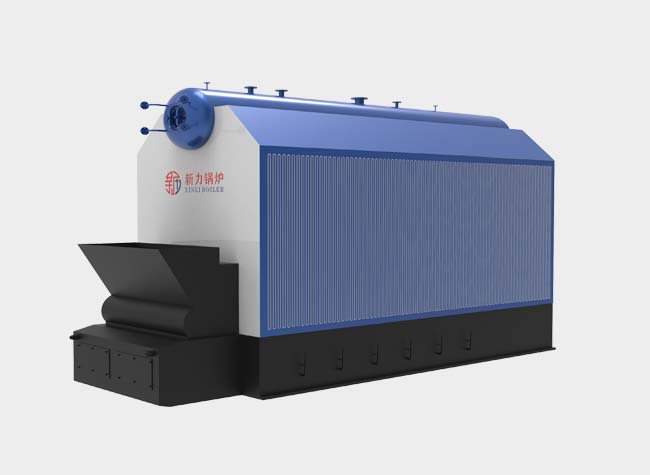

Boilers for hotels are mainly used for heating and sanitary hot water supply, and some hotels also need to supply steam for laundry and kitchen. The traditional hotel boiler is mainly equipped with steam boiler and pressurized hot water boiler. It is heated by plate heat exchanger and supplied with sanitary hot water by volumetric heat exchanger. For hotels, a variety of energy consumption is generated every day, which is related to many factors including the selection of boiler equipment. Using clean energy boilers can help hotels reduce cost.

Boiler Model Selection used for Boiler Used for Hotel

Hotel boilers should meet the needs of the whole hotel, for hot water supplying or room heating, as well as steam for laundry or kitchen, so when choosing boilers, pay attention to what type of boiler (hot water boiler or steam boiler). Hot water boiler is also divided into many kinds, there are vacuum hot water boiler, indirect heat transfer boiler, ordinary atmospheric pressure hot water boiler and so on. In addition, after the selection is determined, the continuity of water supply should be considered. In order to prevent equipment failure to bring losses to the hotel, two boilers could be equipped for the hotel, one for working and another one for stand by.

Boiler Model Recommendation

How to Choose the

Suitable Boiler for

Boiler Used for Hotel

Determine Boiler Medium

For hotel heating enterprises that do not supply steam for industrial production but only provide heating for residents, the first choice is the hot water boiler as the heating boiler. Because the operation of hot water boiler is safer, more stable and more economical than regular boiler, meanwhile, the heating radius of hot water is about twice that of steam, and the maximum heating radius can reach 20 km.

Determine Boiler Capacity

General heating boilers are calculated according to area. For general residential, 1 ton of boiler heating area is 6000~8000 square meters. For the common workshop and other higher places and cold areas, heating area should be relatively reduced.

Determine Boiler Fuel

Boilers are divided into fuel oil gas boilers, coal-fired boilers, biomass boilers, electric boilers. The state strictly controls the coal-fired boilers. The gas-fired boiler should consider whether it is convenient to install the gas pipeline. If it is not convenient, oil-fired or electric boilers should be considered.

Boiler thermal efficiency

Boiler should has high efficiency. The boiler output, the number of sets and other performance can adapt to the demand of heat load change, in order to facilitate economic management. If the use of one boiler operating at full load can meet the demand for steam, it is not appropriate to use two boilers operating under lower load. However, from the perspective of safety production, it is necessary to consider whether a single boiler in operation can be started quickly in a short time due to failure, so as to meet heating requirements without affecting production.

Capacity and Model

It is better to select the boilers with same capacity or combustion equipment. If different, the max limitation is two models, to decrease the problems of equipment layout and management.

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.