Oil Refinery Boiler

Oil refining refers to the process of crude oil distillation, catalysis, cracking, and hydrofining, etc., to produce diesel, gasoline, kerosene, lubricating oil, petroleum coke, asphalt, ethylene. Oil refining equipment could be divided into fluid conveying equipment, heating equipment, heat transfer equipment, mass transfer equipment, reaction equipment and storage equipment. Heating equipment heats the oil to a certain temperature, vaporizes it or offer reaction condition.

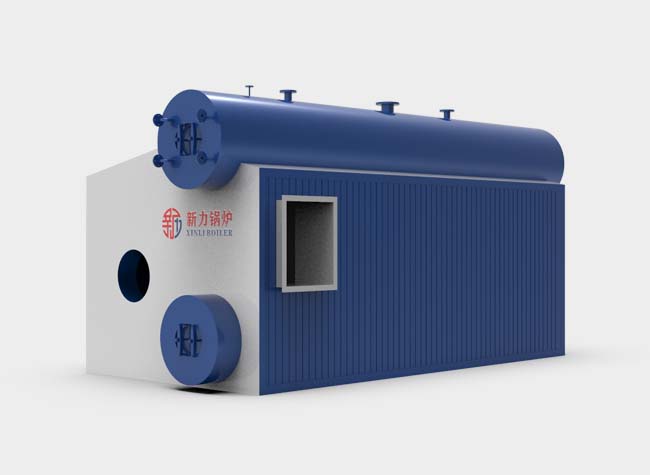

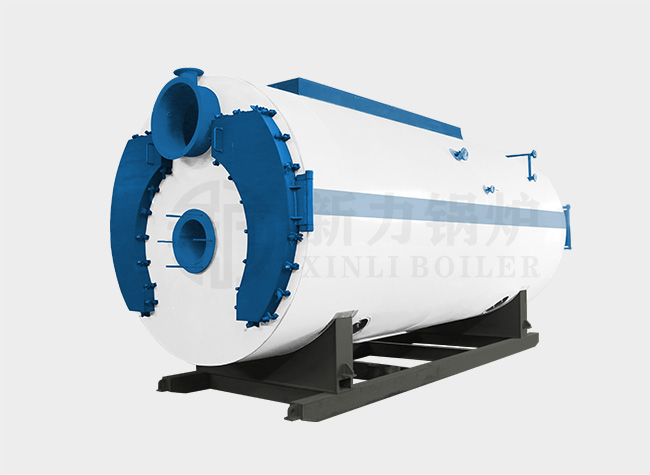

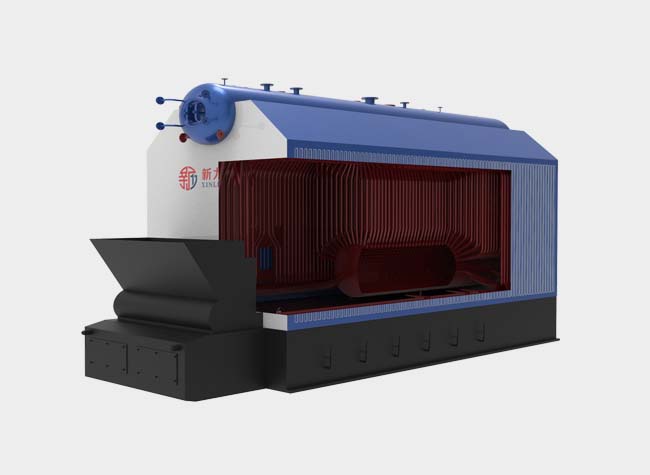

Boiler Model Selection used for Oil Refinery Boiler

The main heating equipment in the factory is steam boiler, which usually uses oil and gas as fuel. In addition, the waste heat of flue gas in oil refining plant can be recycled to heat storage equipment, heat tracing and for central heating in winter. Xinli boiler can provide steam boiler with different capacities for refinery to meet the heat demand for production. At the same time, waste heat boiler can be designed to make full use of waste heat and save energy.

Boiler Model Recommendation

How to Choose the

Suitable Boiler for

Oil Refinery Boiler

Determine Boiler Capacity

Determine the saturated steam parameters of the boiler according to the requirements of the production process. The advantage of saturated steam is that it maintains a constant temperature for production.

Determine Boiler Pressure

Generally, boiler pressure is always higher than the production of saturated steam pressure, the reason is to overcome the pressure loss in the pipe or network. The actual production pressure plus the pressure drop required to overcome all pipe resistance plus a pressure margin of 25 to 30 percent is sufficient.

Determine Boiler Fuel

Boilers are divided into fuel oil gas boilers, coal-fired boilers, biomass boilers, electric boilers. Users have to consider the boiler fuel based on their specific situation including fuel cost and national environmental protection requirements.

Determine Boiler Structure

In addition to boiler output, working medium parameters, fuel types three basic factors, there are other aspects such as external size, load volatility, water quality, air pollution, mechanization, automation degree, and the main and auxiliary machine selection.

Capacity and Model

If two or more boilers are needed, it’s better to select the boilers with same capacity or combustion equipment. If different, the max limitation is two models, to decrease the problems of equipment layout and management.

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.