Paper Processing Industry

Steam is necessary for paper processing industry. Usually, steam is used for drying to improve the strength and smoothness of paper. The water content of wet paper still as high as 53%~70% after squeezing, and it is not useful by using mechanical stress for anhydration, so, use cast iron dryer to dry paper, cooperate with the use of steam boiler. Except drying, it can also use for corrugated paper processing, andsupport the use of calender and glue paste roller. Otherwise, Chemicals (hydroxide, sodium sulfate, sodium carbonate, etc., ) are heated by steam for dissolving sodium.

The traditional papermaking industry is a big consumer, and the flue gas and coal ash of boiler are a big pollution source of paper mill. In recent years, under the guidance of the high pressure environmental protection policy of the state, various places have strengthened the pollution control in the paper industry according to the actual situation. Those small paper mills with relatively backward equipment and energy-consuming production processes have become the main targets for local closures. The number of paper mills on the whole continues to decline, which has greatly affected the paper industry. It can be seen that energy saving and consumption reduction has become one of the main ways for papermaking enterprises to increase production and save, improve economic benefits and enhance product market competition.

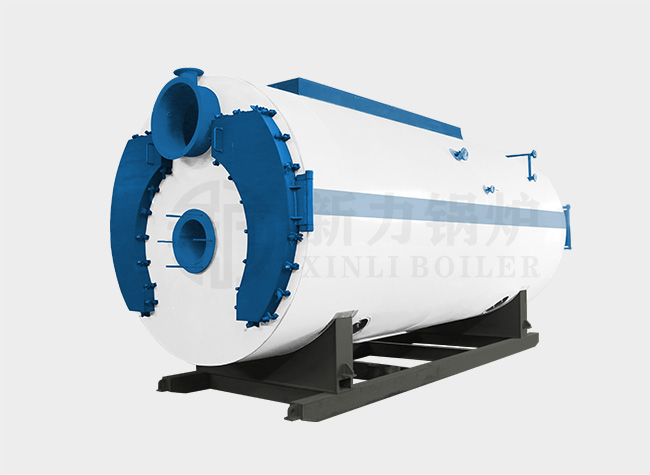

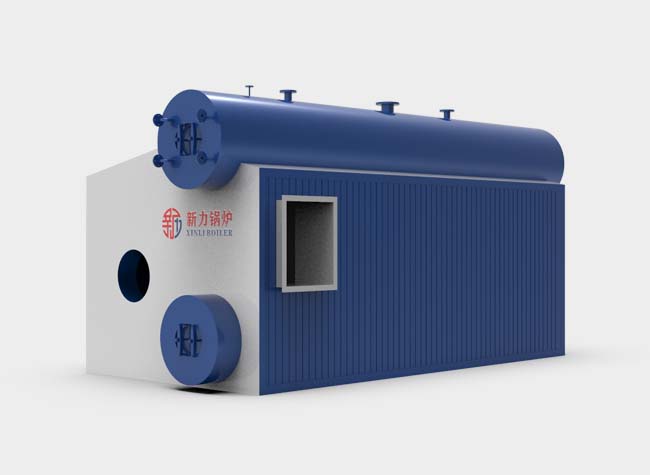

Boiler Model Selection used for Paper Processing Industry

The boiler design and boiler house reasonable layout are directly affect the production reliability, energy consumption index and environmental health conditions of paper mill. In some small paper mills, problems such as unreasonable layout of boiler room equipment, low thermal efficiency of boiler, high coal consumption, dryness and dust, and serious environmental pollution are common. According to the actual needs and environmental protection requirements of customers, Xinli boiler provides the most suitable heating system for domestic and foreign paper mills.

Boiler Model Recommendation

How to Choose the

Suitable Boiler for

Paper Processing Industry

Determine Boiler Capacity

Determine the saturated steam parameters of the boiler according to the requirements of the production process. The advantage of saturated steam is that it maintains a constant temperature for production.

Determine Boiler Pressure

The general boiler pressure is always higher than the production of saturated steam pressure, the reason is to overcome the pressure loss in the pipe or network. At present, the pressure of boiler nameplate is much higher than the pressure needed in production. The actual production pressure plus the pressure drop required to overcome all pipe resistance plus a pressure margin of 25 ~ 30% is sufficient.

Determine Boiler Type

Many paper mills use traditional coal-fired steam boilers, the equipment is relatively backward and cost large energy. More and more paper mills use circulating fluidized bed boilers to reduce pollution emissions and improve combustion efficiency. Oil-fired gas boilers, biomass boilers and corner tube boilers are also suitable for paper mills.

Determine Boiler Structure

In addition to boiler output, working medium parameters, coal varieties three basic factors, there are other aspects such as external size, load volatility, water quality, air pollution, mechanization, automation degree, and the main and auxiliary machine selection. The size of the boiler should be considered in the expansion of the original boiler room. The products of different plants vary greatly in size, so the user should find out the product situation of the factory.

Capacity and Model

When the boiler with different capacity and different types is selected, the boiler with the same capacity and combustion equipment should be selected. If not, try to construct the responsible line of equipment layout and maintenance management. The same model with different capacities or different models with same capacity could be choosed.

Cooperative Partner

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.