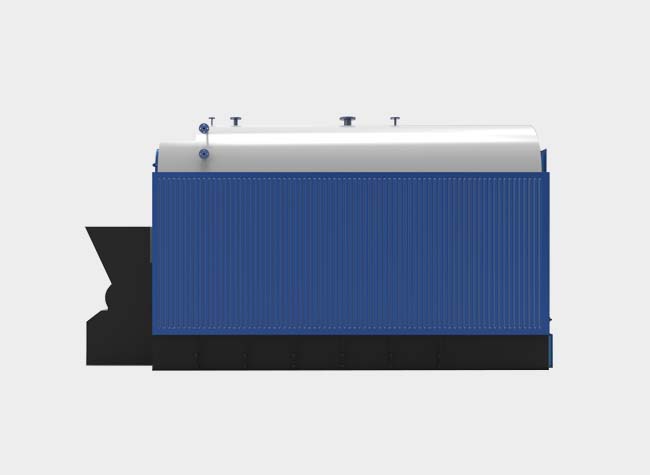

Textile Industry Boiler

In textile production, steam boiler is a necessary heat source equipment, mainly used for dyeing, drying, sizing, printing and dyeing and other technological processes. Textile enterprises are mostly larger in scale and have high requirements for steam quality and high demand for steam per unit time. Therefore, for this kind of project, energy-saving, low cost boiler is the first choice.

The steam output quality of the steam boiler plays a decisive role in the product quality after dyeing and drying in clothing and textile factories. Selecting the steam boiler in domestic textile factories can not only effectively improve the textile quality and production efficiency of textile enterprises, but also reduce the labor cost and the operation cost of the steam boiler to ensure the maximum profit.

Boiler Model Selection used for Textile Industry Boiler

As society's demand for textiles increases, so does the amount of heat used by textile mills. Whether it is the newly built textile factory or the reconstruction and expansion of the boiler room of textile factory, it is a problem of heating boiler selection. Scientific and reasonable boiler selection is important for energy saving, environmental improvement and safety production. According to the actual needs and environmental protection requirements of customers, Xinli boiler has customized heating schemes for textile mills at home and abroad to provide the most suitable boiler heating system.

Boiler Model Recommendation

How to Choose the

Suitable Boiler for

Textile Industry Boiler

Determine boiler capacity

The boiler capacity should based on the Heating Load Curve or Heat Balance Diagram, and includes the heat loss in pipelines, self-used heat of boiler room, available used waste heat. While, usually, it is difficult to get the Heating Load Curve, the heating load could get based on the max thermal consumption per hour within production/heating/domestic, and then determine by using the coefficient.

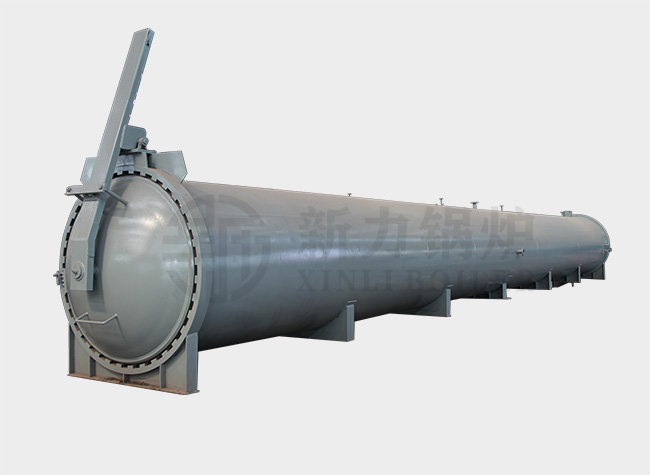

Determine Heating Medium

The demand of medium and the heating system should be determined according to the heating mode. Most textile mills use steam boilers. In recent year, according to different textile equipment, more and more heat conduction oil furnace also put into textile production.

Determin Heating Parameter

The heating parameters of boiler room should be in accordance with the requirements of users' heat parameters. But in the choice of boiler, should not make the boiler rated outlet pressure and temperature and user use pressure and temperature difference too large, so as not to cause high investment, low thermal efficiency.

Determine Boiler Efficiency

Boiler should be more efficient. The boiler output, the number of sets and other performance can adapt to the demand of heat load change, in order to facilitate economic management. If the use of one boiler operating at full load can meet the demand for steam, it is not appropriate to use two boilers operating under lower load. However, from the perspective of safety production, it is necessary to consider whether a single boiler in operation can be started quickly in a short time due to failure, so as to meet heating requirements without affecting production.

Capacity and Model

It is better to select the boilers with same capacity or combustion equipment. If different, the max limitation is two models, to decrease the problems of equipment layout and management.

Cooperative Partner

Contact Us

Resolve Your Problems within One Minute

Address:No.11 Minhe Road, Private Industrial Park, Development Zone, Kaifeng City

Inquiry

If you have any questions about our company and products, please contact us immediately. Any inquiries and Suggestions would be appreciated.

We will keep your information confidential.