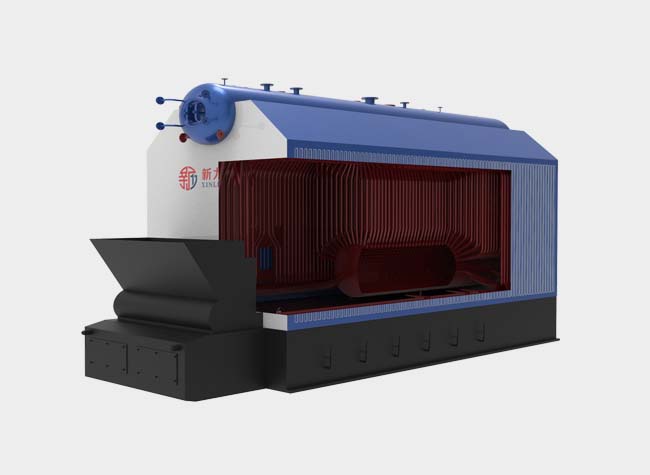

DHL Biomass Fired Corner Tube Steam Boiler

DHL biomass fired corner tube steam boiler is a boiler with large diameter thick-wall drop tube located in the four corners of the boiler and composed of a frame supporting the overall weight. Water cycle is unique and safe, boiler start quickly, structure compact , could effectively save steel and boiler civil construction costs and follow-up maintenance costs. Corner tube boiler furnace and convection heating surface adopt self-supporting structure. Corner tube boiler has high efficiency and energy saving, which is widely used for different industrial production process and for central heating purpose.

This boiler could burn different kind biomass fuel, such as wood chips, rice husk, bagasse, peanut shell, cotton shell, coconut shell, etc. Biomass fuel is renewable green energy with a wide range of sources. Biomass energy will gradually replace coal and become one of the main energy sources. Compared with coal-fired boilers, biomass fuels have lower cost and lower operating cost.

Rated Evaporation Capacity

Working Pressure

Outlet Water Temperature

Avaliable Fuel

Details Preservation

Performance Advantages

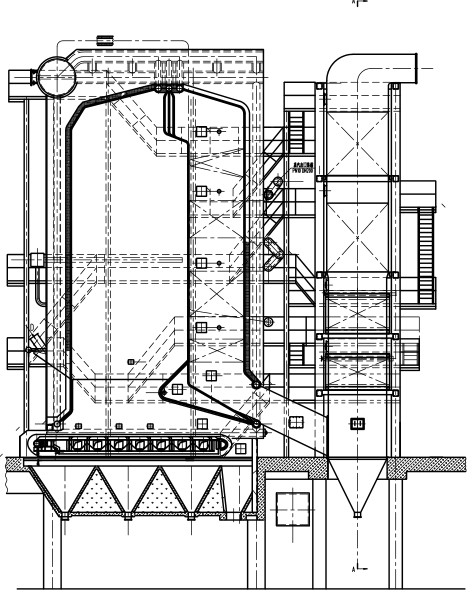

1. The four corners of the corner tube hot water boiler are large-diameter thick-walled downcomers, the boiler is consist with downcomers, boiler drum, water-cooled wall, header, flag-shaped heating surface, and reinforcing beam. No steel frame structure,

2. The drum of the angle tube hot water boiler is external longitudinal arranged or a horizontal arranged, the furnace outlet is arranged at a high position, and the combustion space is relatively sufficient.

3. Fully enclosed membrane water-cooled walls are used around the furnace and the heating surface channel, the furnace has a large cross-sectional area and large volume.

4. Adopts unique flag-type heating surface structure technology, a large number of convection heating surface tubes are led out of the film-type water-cooled wall tubes to form a heating surface like a banner.

5. The grate of the corner tube boiler adopts the scale type or beam type grate, which adopts the isobaric structure of the gale bin. Below the grate surface is a large isobaric chamber. Between the isobaric air bunker and the grate face are several group

6. Could arrange secondary air on the front wall and rear wall of the furnace according to the different fuel types.

7. Economizer or air preheater is arranged at the rear of the boiler, which can absorb the heat of the flue gas, reduce the flue gas exhaust temperature, save energy, and improve efficiency.

Technical Parameters

| Model | Rated Evaporation Capacity(t/h) | Rated Pressure (Mpa) | Rated Steam Temperature(℃) | Feed Water Temperature(℃) |

| DHL20-1.25-AII | 20 | 1.25 | 194 | 105 |

| DHL20-2.5-AII | 20 | 2.5 | 226 | 105 |

| DHL25-1.25-AII | 25 | 1.25 | 194 | 105 |

| DHL25-1.6-AII | 25 | 1.6 | 204 | 105 |

| DHL35-1.25-AII | 35 | 1.25 | 194 | 105 |

| DHL35-1.6-AII | 35 | 1.6 | 204 | 105 |

| DHL35-2.5/400-AII | 35 | 2.5 | 400 | 105 |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | ||||

![<?=$ecms_gr[title]?>](/d/file/20251111/27cc6d78cd23585cafa40fdfb3a6fd4d.jpg)