30t/h CFB Boiler

Circulating fluidized bed combustion technology has the characteristics of high efficiency, clean, and low temperature, it is developed and promoted in recently years. Xinli Boiler takes advantages of the mature advantage of CFB boiler and upgrading the technology, improves the boiler technical performance, energy saving & environmental performance, and operation reliability. SHX is one series of CFB boiler, it takes advantages of high efficiency external circulationg cyclone combustion technology, has the characteristics of high thermal efficiency, high desulfurization rate, compact structure, and easy operation. The boiler could be used in different industrial production and electric generation, it is the ideal alternative heating equipment to the conventional boilers.

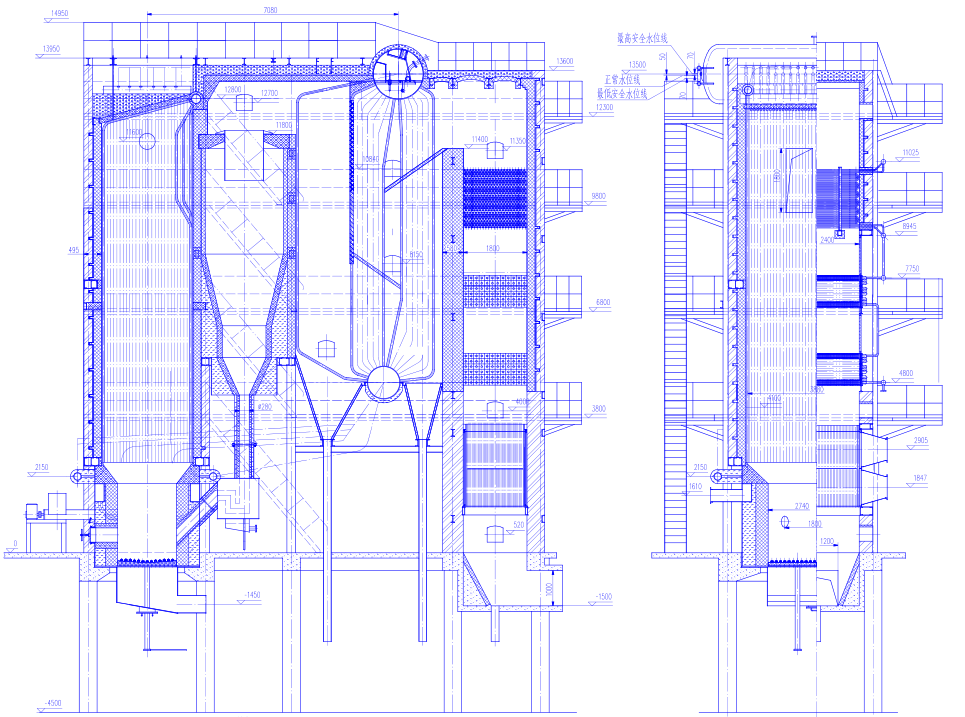

Working Process: The fuel is sent to the furnace by the conveyor, mixed with air in the dense phase region, and then fluidized and burned. The high temperature flue gas carries a large amount of burning solid particles to wash the dilute phase region. When burning, the solid paritcles transfer the heat to the heating surface and heat the water medium at the same time. The unburned solid particles enter into the separator, collected by separator and returned to the dense phase zone for circulated burn through the return feeder, thus the combustion efficiency is increased. The ignited solid fine particles escape from the separator with the high-temperature flue gas, wash the convective heating surface and the tail heating surface, and they are discharged into the atmosphere after being dusted by the dust remover.

Rated Evaporation Capacity

Working Pressure

Steam Temperature

Avaliable Fuel

Details Preservation

Performance Advantages

1. Burn Different Types Solid Fuels

The temperature in furnace is 850℃~950℃, the fuel particle could reach to furnace temperature and burn rapaidly. Thus, CFB boiler could burn different type solid fuels without any auxiliary fuels.

2. High Combustion Efficiency

the fuel is mixed with a large amount of high temperature bed fuels and burn rapidly, and has high combustion rate. The unburned particles are returned to furnace for circulating cumbustion by cyclone separator, lengthen combustion period, and increase co

3. Excellent Desulfurization Effect

Desulfurization process is processed under the optimum reation temperature in furnace, and the circulating system could lengthen the residence time of desulfurizer in boiler, also, the desulfurizer particle size is small as 0.1mm, the reaction contact are

4. Low NOx Emission

The furnace temperature is keep at 850℃~950℃, the temperature is relatively low, so the NOx emission is less. Otherwise, CFB boiler adopts zoning air supply and zoning combustion, the fuel could burn sufficiently, low NOx emission.

5. High Heat Load of Furnace Cross Section

Strong mixing and fast heat transfer in furnace, the furnace cross section has high heat load (around 3~5MW/㎡).

6. Slag Could be Utilizated comprehensively

The fuel is combusted under low temperature, and the high combustion efficiency makes slag has low carbon content, also, there are large amount of calcium oxide and calcium sulfate, could used for cement and brick, etc.

Technical Parameters

The boiler front furnace adopts whole membrane water wall suspension structure. The separation system adopts adiabatic high temperature cyclone separator and automatic balance U type material return device. The convection tube bundles between the upper and lower drums ensure sufficient heating surface. The economizer adopts two-stage cast iron economizer, and airpreheater is arranged at the boiler tail.