YLW Coal Fried Thermal Oil Heater

YLW coal fired thermal oil boiler is a kind of new type heating equipment, the fuel could be coal, biomass or flue gas, the heat carrier is heat conduction oil, the circulating pump force heat transfer medium circulating in liquid phrase, and transfer heat to heat user equipment, then return to the heating furnace for reheating. It is an safe and low energy consumption boiler with working characteristics of low pressure (1.0 MPa) and high temperature (350℃). The boiler medium is working under liquid state, so it is safe and reliable.

Thermal oil boiler could instead steam boiler for industrial production, to improve productivity. Xinli thermal oil boilers are widely used for petroleum chemical industry, Oleochemical industry, Synthetic fiber industry, textiel printing and dyeing industry, plastic and rubber industry, paper industry, wood industry, building materials industry, machinery industry, food indstry, electrical equipment industry, coking industry, etc.

Rated Thermal Power

Working Pressure

Highest Temperature

Avaliable Fuel

Performance Advantages

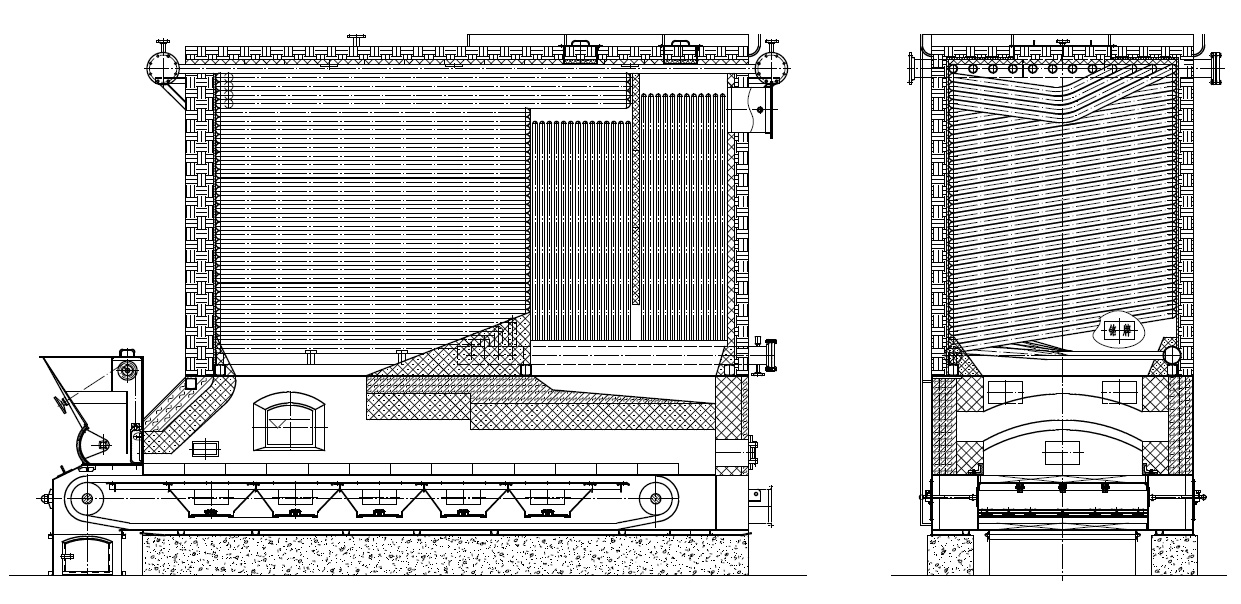

1. Strong adaptability of different fuels. The combustion equipment and the upper furnace is separately, the furnace could be designed individually according to the different solid fuel characteristics.

2. Equipped with full automatic chain grate, save labor cost.

3. The combustion chamber is composed of chain grate and back&front arch, large combustion space, the fuel could combust completely, has high efficiency.

4. Reasonable arrangement of heating surface, large heating area and good heat transfer efficiency, achieve high efficiency and enough output.

5. Radiation section adopts square coil, the convection section coil adopts serpentine coil, the coil at radiation surface has good thermal expansion, low stress, safe and reliable.

6. Temperature control precise and reliable. The boiler is equipped with a complete operating control and safety monitoring device, a high degree of automation, labor intensity is low.

7. Saving energy and reducing consumption, compared with the steam heating it can save energy 1 to 1.5 times, compared with the electric heating energy saving 0.8 to 1.3 times, saving operating cost obviously.

Technical Parameters

| Model | Rated Thermal Power (KW) | Working Pressure (MPa) | Highest Working Temperature (℃) | Thermal Efficiency (%) | Overall Dimension of biggest part for transfortation L×W× H (mm) |

Weight of biggest part for transporation(t) |

| YLW-1400MA | 1400 | 0.8 | < 350 | 75 | 4121×1900×2900 | 14 |

| YLW-3000MA | 3000 | 0.8 | < 350 | 78 | 6000×2650×3240 | 30 |

| YLW-4200MA | 4200 | 0.8 | < 350 | 78 | 6900×2820×3470 | 40 |

| YLW-6000MA | 6000 | 0.8 | < 350 | 78 | 7900×3200×3475 | 48 |

| YLW-10000MA | 10000 | 0.8 | < 350 | 81 | 9200×3300×3550 | 70 |

| YLW-12000MA | 12000 | 0.8 | < 350 | 85 | 12600×3820×3630 | 142 |

| Note: Parameter is for reference only, if any changes should follow the technical drawing | ||||||