Mixed Chemical Waste Heat Recovery Boiler

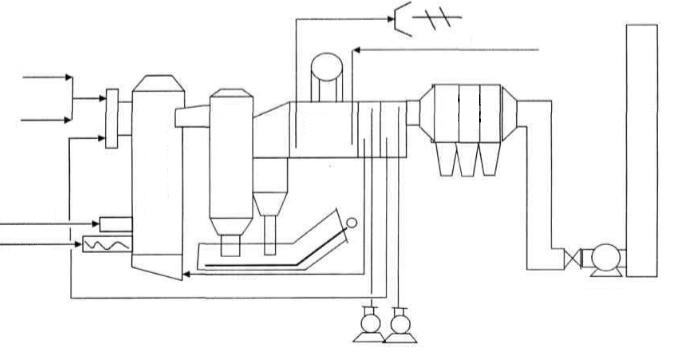

Mixed waste heat recovery boiler burners is a high efficient and energy saving product, it recycles the waste heat, which comes from the combustion of mixed exhaust gas, raste residue, and waste heat. The characteristics of the waste gas are high temperature heat (800 to 1000 degrees Celsius) and high dust content (15g / Nm3). This type boiler is an economic energy saving equipment for chemical plant, it works with “three waste” combustion furnace and blowing furnace, realizes "two coals as one coal", "two furnaces as one furnace" for companies. It can create a huge economic and environmental benefits, safe, environmental protection, efficiency and energy savings. The boiler is composed of water-cooled screen, superheater, convection tubes, economizer and air preheater.

Rated Evaporation Capacity

Working Pressure

Steam Temperature

Application

Details Preservation

Performance Advantages

1. High Efficient Heat Transfer

Heat transfer of exhaust gas and water/steam is proceed on surface, the outside of exhaust gas heat pipe is fin, so the heat transfer area increases, and the heat transfer coefficient increases.

2. Anti-ash-deposition, anti-ash-fouling, anti-corruption

The temperature of tube wall can be adjusted by adjust the ratio of hot and cold surface on heat pipe. Increases the temperature and let it higher than the dew point temperature or maximum corrosion area, which can prevent corrosion, extend the life of he

3. Long Operation Life

It is easy to adjust the smoke speed, so that the smoke speed of each section is even, and the layout of the heating surface of each section is more reasonable, dust accumulation, abrasion and other problems are solved, to ensure the boiler heating surfac

Technical Parameters

| Model | Rated Evaporation Capacity (t/h) | Rated (MPa) | Rated Steam Temperature (℃) | Exhaust Gas Temperature (℃) |

| Q70/930-25-3.82/450 | 25 | 3.82 | 450 | 150 |

| QC80/850-25-3.82/450 | 25 | 3.82 | 450 | 150 |

| Q60/950-25-3.82/450 | 25 | 3.82 | 450 | 168 |

| QC125/950-50-3.82/450 | 50 | 3.82 | 450 | 148 |

| QC185/930-60-5.29/485 | 60 | 5.29 | 485 | 150 |

| Q215.5/863-60-5.29/480 | 60 | 5.29 | 480 | 140 |

| Q193/875-65-5.3/490 | 65 | 5.3 | 490 | 143 |

| QC200/930-80-3.82/450 | 80 | 3.82 | 450 | 150 |

| Note: Xinli Boiler could customize design the waste heat recovery boiler based on the actual demand | ||||