Carbon Rotary kiln waste heat boiler

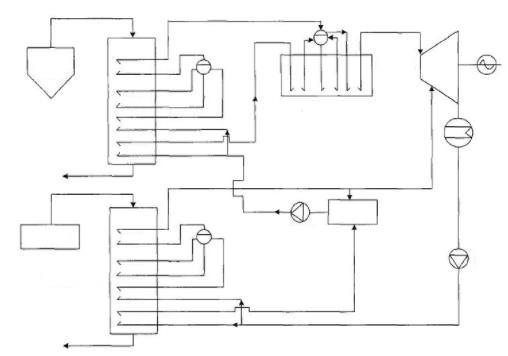

Carbon rotary kiln waste heat boilers use the waste heat of the exhaust gas from carbon rotary kiln or tank carbon calciner, to produce the superheated steam for turbonator or life. After calcination, the gas has high temperature (900 to 1100 degrees Celsius), low dust content (~ 5g / Nm3), and a higher content of SOin the flue gas, based on this, the waste heat in our company solves the above problems, it emploies the vertical structure to reduce area occupation, the rectangular fin and membrance wall reduce the volume of the boiler.

Rated Evaporation Capacity

Working Pressure

Steam Temperature

Application

Details Preservation

Performance Advantages

1.Vertical positioned

Structure compact, compare with the traditional carbon rotary kiln waste heat boiler, occupies small areas, low investment on infrastructure, advanced structure and superior performance.

2.Steel tube economizer

High mechanical strength, shock resistance, strong adaptability to load, easy to operation.

3.Inertial separation principle

Two stage separation of gas and solid in furnace, high dust removing efficiency, and protect the environment.

Technical Parameters

| Model | Rated Evaporation Capacity (t/h) | Rated Pressure (MPa) | Steam Temperature (℃) | Exhaust Gas Temperature (℃) |

| Q11/950-4-2.5/400 | 4 | 2.5 | 400 | 190 |

| Q11/950-4-2.5/450 | 4 | 2.5 | 400 | 170 |

| Q11/900-4-2.5/400 | 4 | 2.5 | 400 | 155 |

| Q15/800-5-2.6/400 | 5 | 2.6 | 400 | 180 |

| Q15/800-5-2.6/400 | 5 | 2.6 | 400 | 180 |

| Q26.8/900-9.8-2.5/400 | 9.8 | 2.5 | 400 | 159 |

| Q38.2/930-15-2.5/400 | 15 | 2.5 | 400 | 148 |

| Q50/1100-25-2.5/400 | 25 | 2.5 | 400 | 150 |

| Q72/860-25-3.82/450 | 25 | 3.82 | 450 | 189 |

| Note: Xinli Boiler could customize design the waste heat recovery boiler based on the actual demand | ||||