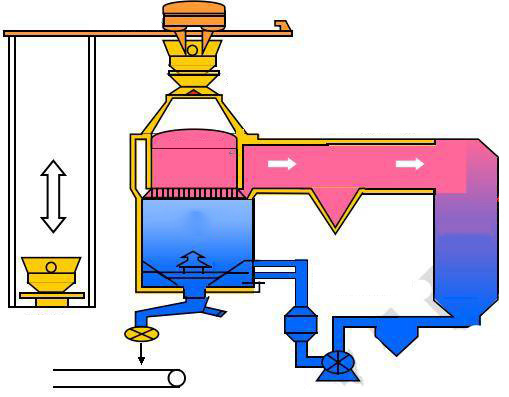

CDQ Waste Heat Boiler

CDQ waste heat boiler is used by coking industry, the inert gas is used as a medium to cooling high-temperature coke, the absorbed inert gas is passed to the boiler, and then fed into the coke oven by circulating fan for recycling, to achieve high-temperature waste heat recovery.

CDQ device has a good energy saving, reduce costs, reduce environmental pollution, sets of high quality coke and many other advantages. I developed this type of waste heat boiler has been widely used, it is an effective solution to the particular problem of boiler seals, wear, expansion, etc., fully able to adapt to the CDQ system load changes.

Rated Evaporation Capacity

Working Pressure

Steam Temperature

Application

Details Preservation

Performance Advantages

1. Recovery Waste Heat, Energy Saving.

80% waste heat can be recovered by using the coke dry quenching technology.

2. Air Tightness Measures

Coke-quenching boiler operates under negative pressure. If the sealing is not good, the leaking oxygen will cause coke combustion in the coke quenching tank, and the leakage of corrosive smoke will aggravate the corrosion of the heating surface. In boiler

3. Environmental protection.

Steam produced by CDQ boiler is used for generate electricity, emissions of SO2 and CO2 comes from fuels (oil, gas, etc) combustion is reduced.

Technical Parameters

| Model | Rated Evaporation Capacity (t/h) | Rated Pressure (MPa) | Rated Steam Temperature (℃) | Feed Water Temperature (℃) |

| Q45/850-15-2.45/400 | 15 | 2.45 | 400 | 104 |

| QC170/650-35-3.82/450 | 35 | 3.82 | 450 | 104 |

| Q90/950-35-3.82/450 | 35 | 3.82 | 450 | 105 |

| BQ36/650-35-3.82/450 | 35 | 3.82 | 450 | 104 |

| BQ60/800-35-3.82/450 | 35 | 3.82 | 450 | 150 |

| Q158.7/700-35-3.82/450 | 35 | 3.82 | 450 | 104 |

| Q130/850-45-3.82/450 | 45 | 3.82 | 450 | 142 |

| Note: Xinli Boiler could customize design the waste heat recovery boiler based on the actual demand | ||||